Contributed by Abby Roth, Founder/Microbiologist, Pure Microbiology

Q. What’s the best starting point for aligning with the current USP <797> (2024)?

Begin with a formal gap assessment against the current <797> requirements. If your organization hasn’t done this yet, it is way behind other sterile compounding pharmacies. Be ruthlessly objective. Observe real work practices and compare them to your SOPs; what’s on paper often diverges from daily practice. Prioritize high-risk findings (e.g., personnel practices, engineering controls, viable sampling trends) before lower-risk issues.

Q. What personnel competency elements do inspectors and surveyors expect for USP <797>?

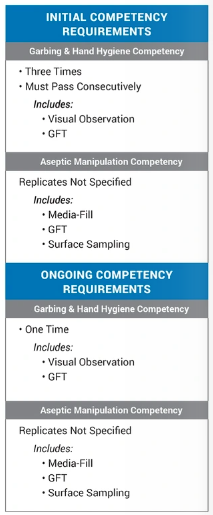

Obviously, initial and ongoing didactic training and the chapter defined hand hygiene and garbing competency and aseptic manipulation competency are going to be of interest. The table to the right highlights the required elements.

Inspectors and surveyors are increasingly focusing on training and competency assessments for surface sampling and colony-forming unit (CFU) enumeration. These are critical activities that often benefit from outsourced training unless internal staff have been formally trained by a subject matter expert (SME) using a train-the-trainer model. Competency assessments may be obtained from external vendors or developed internally.

Q. For USP <800>, where do organizations most often struggle?

One of the most common areas of noncompliance is developing a compounding workflow that fully aligns with USP <800> requirements. Sterile HD compounding is inherently deliberate and must be approached with patience and respect for the process. While patient care is always a priority, staff safety must not be compromised.When evaluating your HD sterile compounding process, ensure the following:

• A new pair of outer sterile gloves is donned at the start of each preparation.

• Hands remain inside the containment primary engineering control (C-PEC) until the compounded sterile preparation (CSP) is complete and decontaminated.

• Each CSP is decontaminated before being removed from the C-PEC.

• Outer gloves are removed and discarded inside the C-PEC.

• A new pair of outer gloves is donned before removing the CSP and placing it into the transport bag.

This is easier said than done. Take time to carefully observe your workflow, identify points of difficulty, and develop practical solutions that maintain full compliance with the chapter. The exact approach will vary by organization and workflow design.

Q. Is the use of closed-system drug-transfer devices (CSTDs) mandatory?

Under <800>, CSTDs are required for administration of antineoplastics when the dosage form allows. For compounding, they’re generally recommended but not required. If a CSTD is not used, ensure staff are trained in the negative-pressure compounding technique.

Q. How do you find the right sized viable sampling plan without overdoing it?

Begin with the minimum sampling frequencies and locations specified in the standard, based on the CSP category being compounded, and then conduct a risk assessment. Although the chapter does not explicitly require a risk assessment to determine viable sampling sites, it does state that locations must be risk-based — so performing one is the most defensible way to demonstrate compliance. Once your plan is established, trend excursions and overall microbial recovery data. Review all sampling results annually to confirm that each location continues to provide value. It’s often best to oversample during the first year to better understand your facility’s microbial profile, then refine and reduce sampling as data supports.

Q. How do we know if the microorganisms recovered on samples with exceeded action levels are of concern?

There are a few lists out there about concerning microorganisms like WHO’s Bacterial Priority Pathogens List, 2024, FDA’s Bad Bug Book, and FDA’s rule titled “Establishing a List of Qualifying Pathogens Under the Food and Drug Administration Safety and Innovation Act”, but they are more applicable to public health and not specific to the pharmaceutical/compounding industries. This really leaves the aseptic manufacturers and sterile compounders on their own to evaluate the microorganisms recovered. Now, the aseptic manufacturers have microbiologists on staff to assist with this. For the sterile compounders, it is critical that they partner with a microbiologist or infection preventionist. The pharmacy can’t do this on their own. Some labs provide organism monographs that may be helpful, but that shouldn’t be the sole source of determining risk.

Q. USP <797> discusses garbing accommodations. Should this be something we allow for?

Possibly. In certain cases, a garbing accommodation may be appropriate and still allow a staff member to compound safely without compromising CSP quality or environmental control. However, proceed with caution — granting a few accommodations can quickly expand without clear oversight. Establish a defined process for evaluating any proposed accommodation and document the following:

• Start Date

• End Date (if Applicable)

• Individual Receiving the Accommodation

• Description of the Accommodation

• Rationale Demonstrating That CSP and

Environmental Quality Remain Uncompromised

Q. Does each certification technician performing cleanroom certification need special credentials?

No. USP <797> does not specifically require certification technicians to hold credentials. However, having trained and credentialed professionals perform the testing offers clear advantages. Ideally, at least one member of the certification team at your facility should hold the Controlled Environment Testing Association (CETA) National Board of Testing (CNBT) credential for pharmacy cleanroom certification. If biological safety cabinets are being tested to NSF standards, the certifier should also possess an NSF or equivalent credential to ensure accuracy and compliance.