Infection control in the clinical environment is critical. Pathogens can proliferate on a variety of surfaces in medical facilities and when these pathogens come into contact with patients, the results can be dire. Depending on the species type, temperature, humidity and other environmental factors, microorganisms can survive on surfaces anywhere from hours to months. Even with standard cleaning, a mosaic virus was shown to spread from one contaminated keyboard to 10% of the high-touch surfaces in an ICU within 48 hours.

Hospital-Acquired Infections

Hospital acquired infections (HAIs) happen in general wards as often as 4% to 8% of patients, 15% of ICUs ,and in up to 50% of the very highest risk areas. These infections can be endogenous, ie, already present in the patient’s body, or exogenous, transmitted to the patient by medical personnel often through invasive measures such as catheter manipulation, surgery, or intubation, as well as through the air or by coming in direct contact with a contaminated surface.

Surgical site infections are an important cause of mortality in the United States, with infections occurring in 2% to 5% of all inpatient surgeries and a 2 to 11 times higher risk of death. These infections cost up to $10 billion dollars annually.

Why HAIs Occur

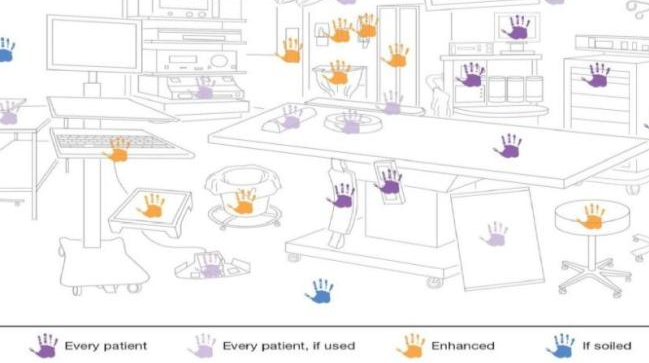

HAIs are common because of a combination of the nature and the volume of increasingly complex invasive procedures and the lack of adequate infection control. In fact, as many as half of HAIs could be avoided by improved compliance with infection control protocols. Some of the most contaminated surfaces in the healthcare environment are keyboards, IV pumps, patient monitors, and the carts and arms that hold these devices.

In addition to personal hygiene (ie, proper hand washing), cleaning, disinfection and sterilization using validated processes, infection control can be enhanced by the hygienic design of high-touch medical products. This means incorporating a design and using production materials that contribute to cleanliness. Antimicrobial surface technology is one hygienic design concept that can be employed to reduce the proliferation of microbes on a surface. Such technologies have intensive and broad antimicrobial activity, are non-toxic, do not induce antibiotic resistance, are permanent, noncorrosive, uncomplicated, and cost effective.

Cleaner By Design

We at TouchPoint Medical recognize that cleanliness in the healthcare environment is paramount to help reduce the spread of HAIs. That is why we partner with Microban® to provide powerful antimicrobial protection in several of our product lines, including workstations on wheels, medication delivery carts, and automated dispensing cabinets. Microban antimicrobial technology is infused into these products during the manufacturing process to inhibit the growth of bacteria on surfaces. The technology becomes part of the molecular structure of the treated product to ensure long-term protection that will not wear away or wash off. Our competitors use antimicrobial finishes that are coated topically or sprayed on, which may chip off.

In lab studies Microban’s customized antimicrobial technologies for healthcare equipment have been shown to reduce bacteria such as MRSA, Ecoli, and VRE by up to 99.9%. Even after repeated contamination, Microban-protected products reduced bacteria on high-touch surfaces and remained cleaner between washings and reduce the spread of bacteria on high-touch surfaces, according to Microban International. In a recent whitepaper written by Dr. Gina Sloan from Microban International, Antimicrobials In Healthcare, it states that “these surface treatments last the life-span of the product and provide a means to continuously control microbial burden on the surface”.

Other hygienic design features these TouchPoint Medical solutions employ include fanless charging options on powered carts that reduce the circulation of dust, debris, and other harmful contaminants to ensure sterile environments are not compromised helping to improve infection control. Advanced polymer and other proprietary finishes like anodized extruded aluminum columns provide corrosion resistance. Products are designed with rounded corners that eliminate crevices and tough-to-clean areas.

Conclusion

Microban technology leveraged by TouchPoint Medical solutions represents part of a systems approach to creating cleaner healthcare environments. Microban is a globally recognized brand with more than 30 years’ experience in the industry.