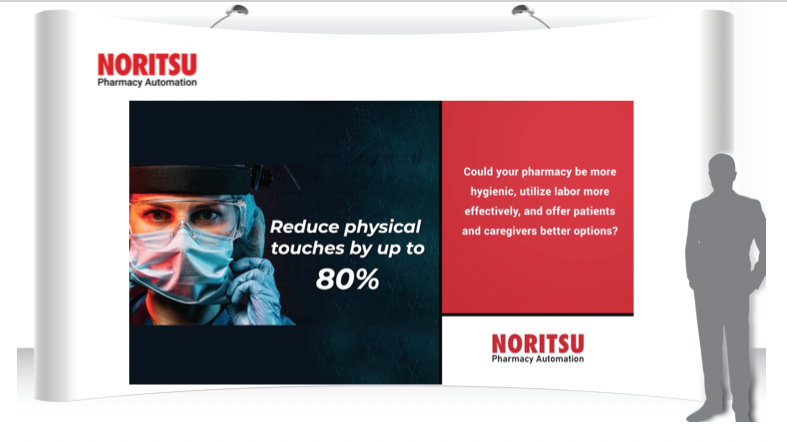

Noritsu Medical

Pharmacy Automation Solutions

Increase accuracy, improve throughput, and save space in your facility, while reducing labor. Whether its adding strip pouch packaging equipment to your existing workflow, introducing verification to your pharmacy, or building a pharmacy from the ground up, Noritsu Medical Group offers state of the art pharmacy automation solutions. Our product offering provides for unit-dose and multi-dose packaging, labeling, and medication delivery hardware and software as well active, on-site, integration, and training.

For over 35 years, Noritsu has earned long term relationships with its customers by providing customized solutions and fast, reliable, personable service. Our nationwide service team is directly employed, not contracted, with an average tenure of 14 years. We understand that every business is different, so our company culture is to provide individualized service in order to build trust and success. To us, you are not just a number; you are an important business partner that needs reliable equipment and support.

Strip Packaging Systems for Unit/Multi Dose: The Xana Z Series, 2040, 3002 and 4001

Accurate, fast, and reliable, Xana strip packagers feature a unique design engineered around efficient pharmacy workflow. Our software prompts operators to proactively address inventory allocation and changes at the most beneficial time in order keep production uninterrupted. The space saving vertical drawer design stores and secures up to 400 unique oral solid NDC cassettes and allows easy refilling and stock rotation, while the patented “Intelligent Feeder” system ensures the highest level of accuracy.

You don’t have to be an engineer to appreciate the build quality of this equipment. Once you see, hear, and feel how smoothly the Xana Series operates, you’ll have confidence in its reliability. Reliable equipment means you can spend more time building your business.

- “Built to Last” – Best in class build quality, backed with nationwide service and support

- Precise dispensing and packaging with the “Intelligent Feeder” system

- High-quality pouch printing-include patient data and photo ID clearly printed on the pouch

- Easy to use interface that can be integrated into virtually any workflow

Medication Detection and Verification Machines: The MDM Series

The MDM series of detection systems offer state of the art medication validation by patient regimented pouch and dose analysis. Built with durability and accuracy in mind, an MDM system can increase your workflow dramatically by quickly checking every pouch for accuracy against a library of medications.

- Three models available to fit the needs of any size facility or application with pouch.

- Quickly and accurately confirm medication dispensing and packaging matches prescription instructions for each patient

- Proprietary software images each pouch for confirmation now and in the future

- Multiple seat capability to match small and large operations for detection review and checkout